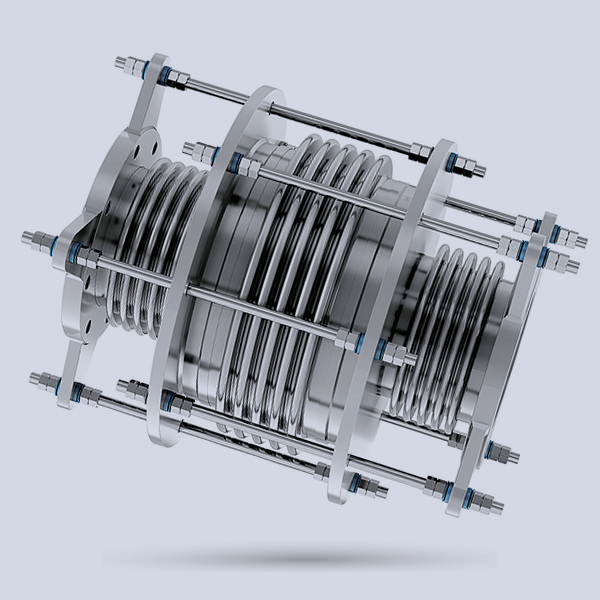

Inline Pressure Balance

Expansion Bellows

Pressure Balanced Expansion Joints are devices which produce no pressure thrust forces in the piping system on the main anchors. In addition to eliminating the pressure thrust, the expansion joint can accept axial compression, axial extension, lateral and angular movements. The balancing thrust is created by using balancing bellows.

This expansion joint is usually used in straight pipe run between two load sensitive delicate equipment where minimum forces and movements are required and main anchor is not possible.

Balancing bellow having twice the area of the line bellow to create an annular pressure chamber that produces a balancing pressure thrust force.

The typical arrangement of the tie rods transfers and balances the pressure thrust.

In-Line Pressure Balanced Metal Expansion Joints consist of single or double (universal) bellows to accept the piping induced axial compression, extension and lateral movements. An oversize bellows with approximately two times the area of the flow bellows is used to create an annular pressure chamber that produces a balancing pressure thrust force. Tie rods are used to link the bellows elements and contain the pressure thrust force. In-Line pressure balanced expansion joints are typically used in straight pipe runs between intermediate anchors (non-pressure thrust resistant) or adjacent to rotating.